Welcome To

Surface Stock

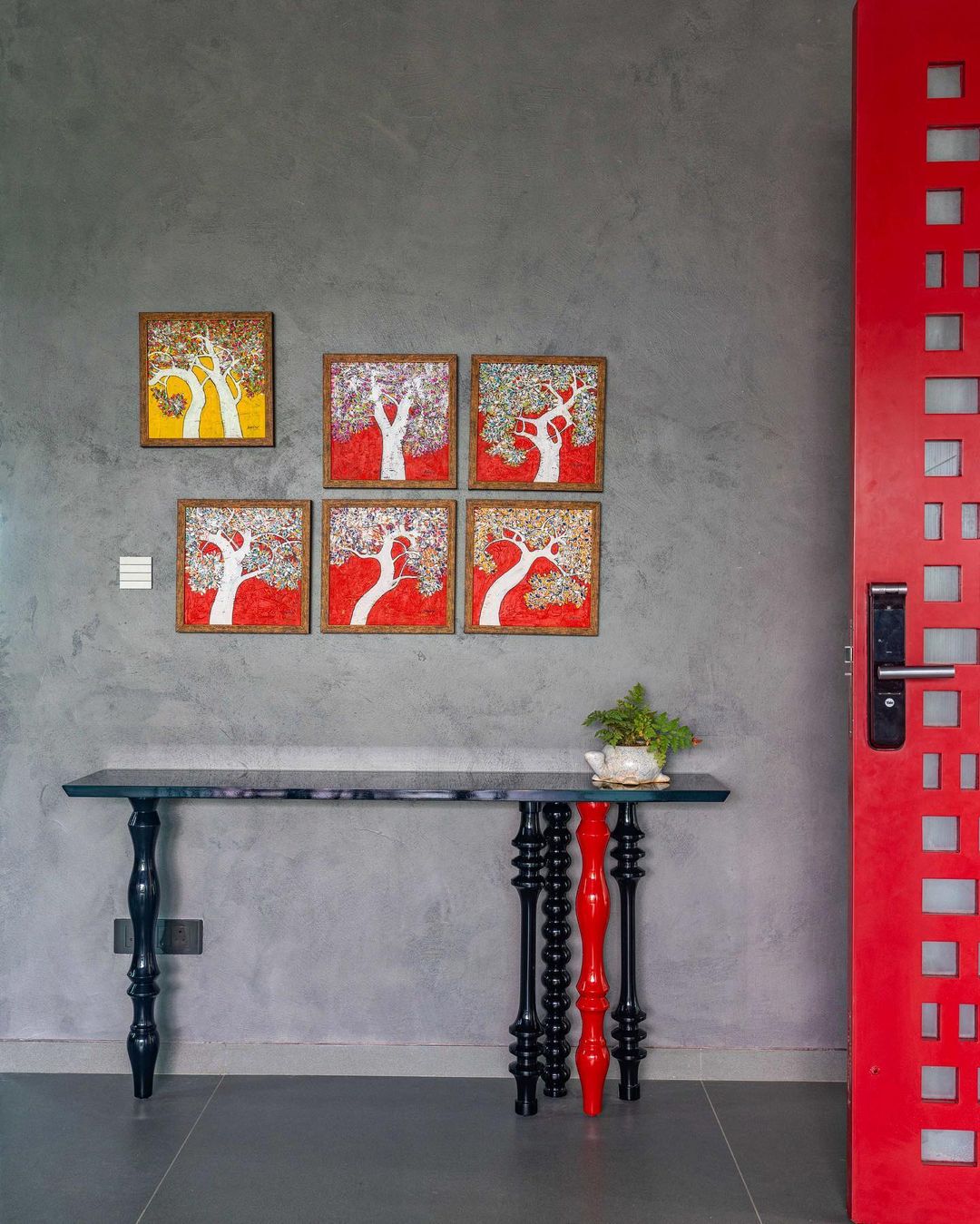

Natural plasters and finishes are eco-friendly. They are made mostly of materials directly available in nature and which require little or no energy for their processing. They are therefore more healthy.

Lime is obtained by firing limestone. It is a traditional material produced all around rural India and can be used as a replacement of cement to obtain waterproof plasters. Lime based finishes are also suitable for external walls as well as internal spaces that are humid, such as kitchens and bathrooms.

Stone dust is the replacement to river sand in traditional plasters. Unlike river sand that is mined from ecologically sensitive areas, stone/quarry dust is crushed and powdered granite chips, a byproduct of the stone mining industry. It is an aggregate within the plaster mix and provides it’s skeletal structure. The particle size of the stone dust can be graded and allows us to control the thickness and texture of the plasters.

The materials that we use in the making of our interior spaces have a big impact on the quality of the air that we breathe. A lot of materials that are used regularly in our buildings such as paints, varnishes, glue, laminates, etc release volatile organic compounds (VOC) into the space. Continuous exposure to such compounds will have an ill-effect on our health, and most certainly, on the health of the people involved in the construction and making of the building. The use of natural plasters eliminates exposure to VOC. In fact, they have a positive impact on the air since they help in the regulation of humidity, temperature.

Lime based plasters have the natural ability to absorb this excess of humidity in the air. This moisture is captured and released when there is less humidity in the room during its usage cycle. This property is also believed to enable the plaster to remove certain odours from the air within our homes.

.jpg)